Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

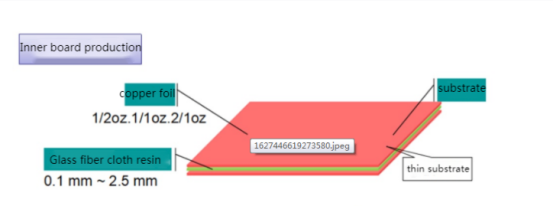

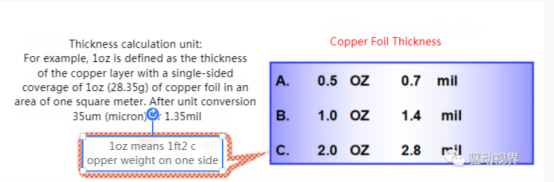

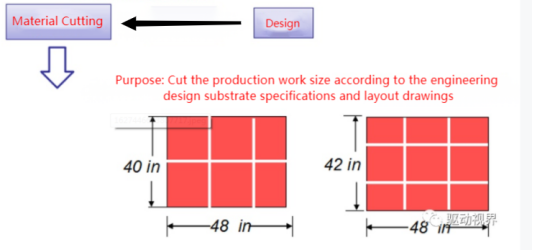

The production process of circuit boards is relatively complicated. Next, we will introduce the production process of double-layer circuit boards.

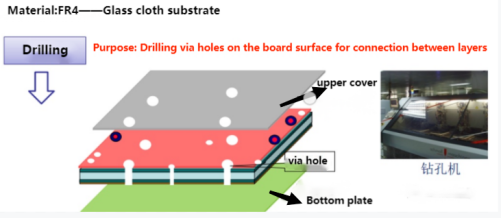

Cover plate (aluminum plate): prevent the drill hole from being burrowed, prevent the burr on the upper surface of the drill hole, protect the copper clad layer from being crushed, improve the hole position accuracy, cool the drill bit, and reduce the drilling temperature.thickness: 0.15mm-0.2mm.

Backing plate (composite plate): It plays the role of protecting the drilling machine table, preventing the export of burrs, reducing the temperature of the drill needle and cleaning the scum of the drill needle groove during production.

Drill bit: Combination of tungsten carbide, cobalt and organic adhesive.

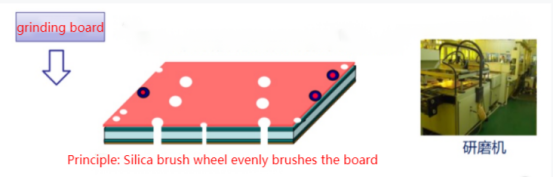

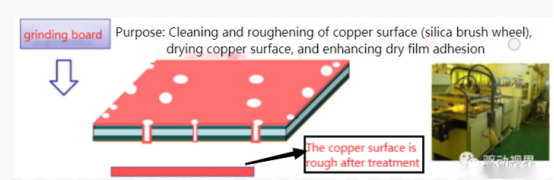

Purpose: To remove the hole burrs, dust and dirt on the board surface produced by drilling, and to provide a clean surface for the subsequent copper sinking layer to adhere well to the board surface and the hole.

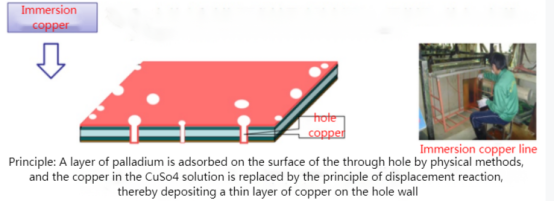

A thin layer of copper is deposited on the entire printed board surface, especially on the hole wall, so that the upper and lower boards are connected, so that the thick copper can be used as a conductor in the subsequent process.

Mail an Lieferanten

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.